Infrastructure

Sourcing:

Unicorn is located in Hyderabad, Telangana which in the vicinity of lush tropical forests that are home to a wide variety of herbs, spices, medicinal plants and other valuable products. Our central location gives us the advantage to cultivate and source quality raw materials from all over India. UNPL works closely with and has established partnerships with various NGO’s, farmers and farming cooperatives, collectors and local tribal folk for the cultivation, collection and sourcing of organic and conventional raw materials. Additionally, to ensure sustainable sourcing our team of agronomists and field experts work with our partners to promote good agricultural practices, and constantly shares with them the post-harvest best practices for cleaning, drying, sorting and storing the raw material.

Commitment to Traceability:

Sustainable and controlled sourcing is the first step to ensure traceability. Our sourcing team ensures diligent tracking and record keeping at the field level, where possible, and this meticulous approach is continued even once the raw material reaches our warehouse. Once the raw material is appropriately tagged, numbered and labelled it moves into production where we maintain batch manufacturing records that have detailed information for the identification of raw materials, solvents and excipients used at various stages. Our unique approach to vertical integration and commitment to transparency help us ensure complete traceability.

Note: Level of traceability will vary from product to product.

Quality Assurance

Highly qualified and experienced specialists make up our Quality assurance team. Our Quality Assurance team starts monitoring the quality of the raw material right from when it is procured through its transformation to the finished extract. There are several quality checks (microbiological, chemical and physical) in place at various stages across the value chain to reiterate the importance the company lays upon the quality of its products. Our vertically integrated approach helps us plug any gaps and guarantees a quality product

Quality Control

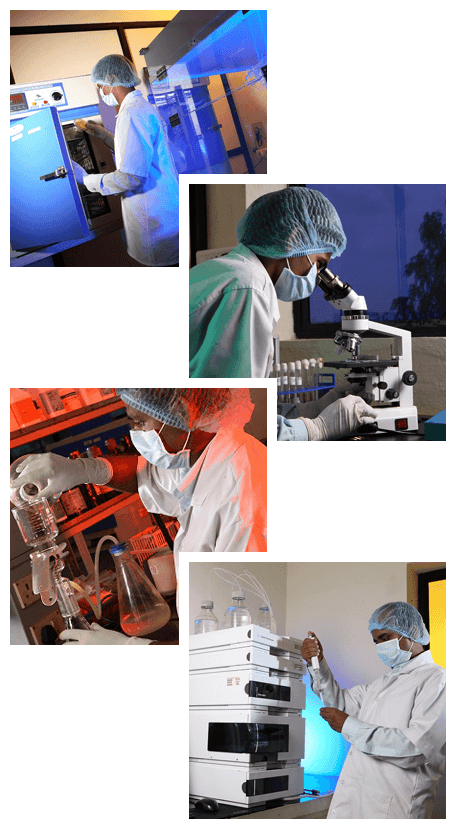

Every batch of each product is tested for organoleptic properties, active components, contaminants and microbiological parameters, using up to date, industry standard testing methods, before it is passed by QC as fit to be sold. Our laboratories are equipped with state of the art instrumentation that is constantly upgraded to match and maintain international standards in terms of both, infrastructure and quality of products. These instruments include a pH meter, UV spectrometer, GC (Gas Chromatography), HPLC (High Performance Liquid Chromatography) and AAS (Atomic Absorption Spectroscopy) machines, a sonicator, and a nephelometer among several other standard equipment found in a QC laboratory.

Microbiology Lab

Every batch of each product manufactured is tested for its microbial load at our in-house microbiology laboratory. The lab is well equipped with the necessary equipment, such as autoclaves, incubators, microscopes, hot air ovens, glass distillation unit, petri plates etc. to test for the presence of any unwanted microorganisms at the requisite stages of the manufacturing process.